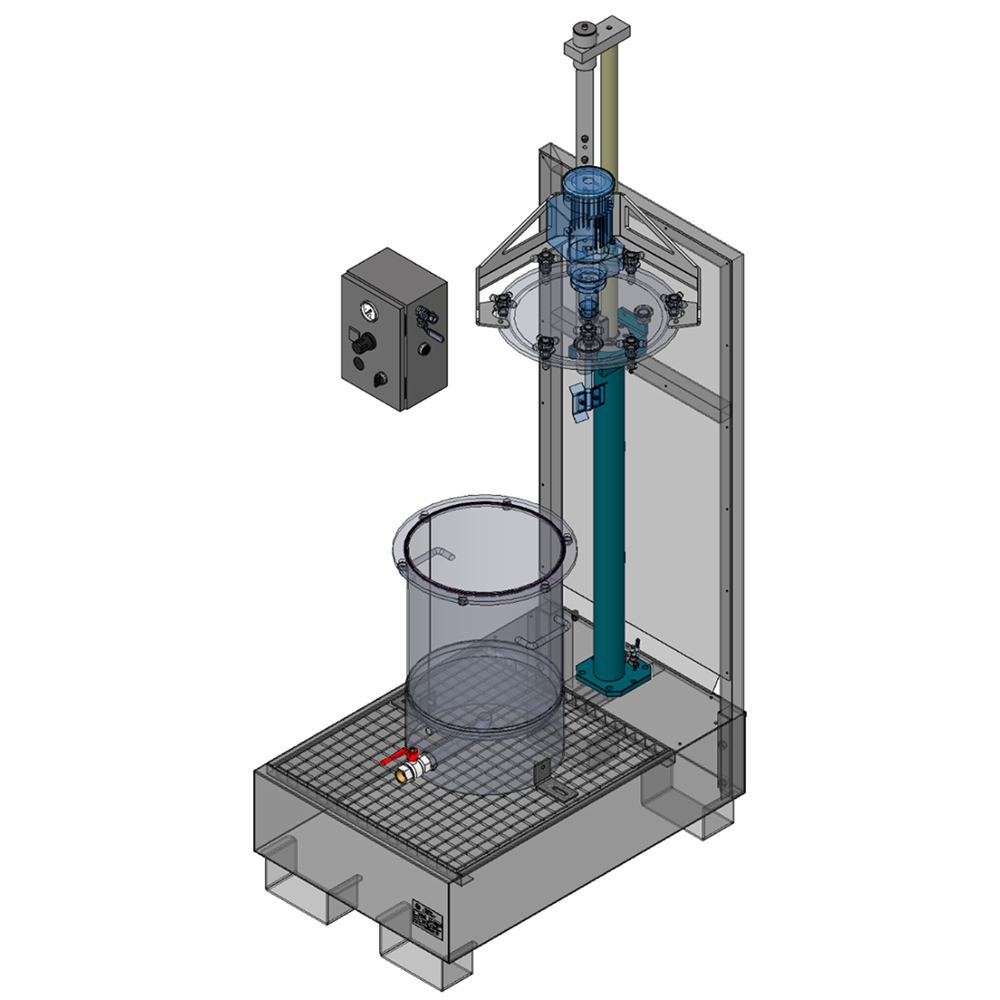

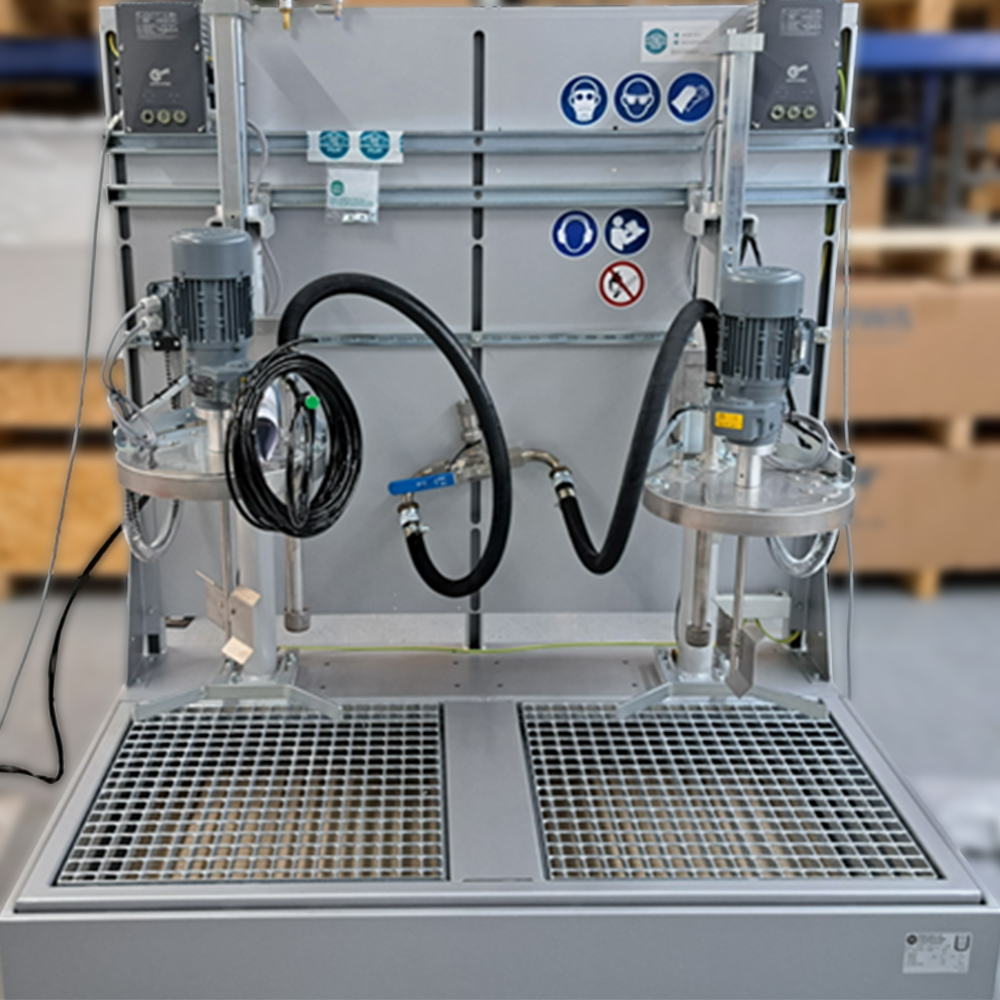

Our 30 litre lid lifter stations are specially designed for the safe storage, preparation and handling of coating materials in the workplace. Whether stirring, homogenising or changing containers - our modular systems ensure ergonomic working, consistent material quality and reliable supply directly in production.

Your advantages at a glance:

![]()

Ergonomic working

no manual lifting of lids - less strain on employees

![]()

Reliable reprocessing

guarantees consistent viscosity

![]()

Safe storage

WHG-compliant collection systems prevent leaks

![]()

Reduced material consumption

closed systems minimize material losses