Quality and process optimisation

Initial situation - what was the customer's problem?

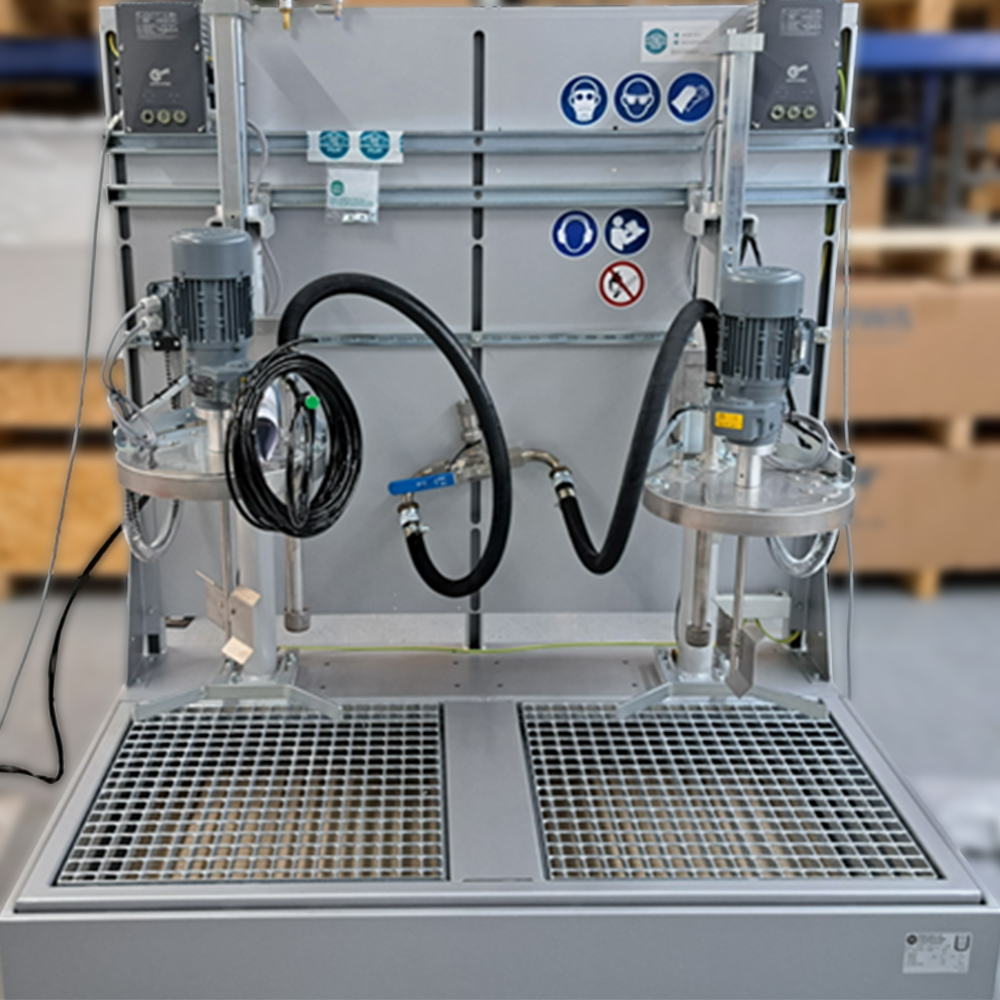

Conversion from 200 liter drums to 2x 30 liter packages

Solution - how could the problem be solved by our system / lifting station?

By optimizing the storage and processing situation, the coating quality was significantly improved. The 200 liter barrel product had the disadvantage that the consumption time was too long.

Too much solvent evaporated through the lid, which did not close tightly, over the dwell time. This process was accelerated by the permanent stirring. In addition, the 200-liter drum could never be completely emptied; there were usually 15 liters of material left over that had to be disposed of.

What advantages has the customer gained from our system / lifting station?

![]() no lifting of heavy loads due to lifting device

no lifting of heavy loads due to lifting device

![]() Adjust the processing quantity to the daily requirement → Always fresh material

Adjust the processing quantity to the daily requirement → Always fresh material

![]() Automatic switchover from empty to full container

Automatic switchover from empty to full container

![]() Intermittent stirring with electrically controlled speed

Intermittent stirring with electrically controlled speed

![]() Fulfilment of all storage regulations

Fulfilment of all storage regulations

![]() Significantly better coating quality

Significantly better coating quality