Applying Adhesive - Types, Methods and Systems

Processing and applying adhesive can present some challenges. Wondering which adhesive application system is best for your material?

Adhesive processing applications

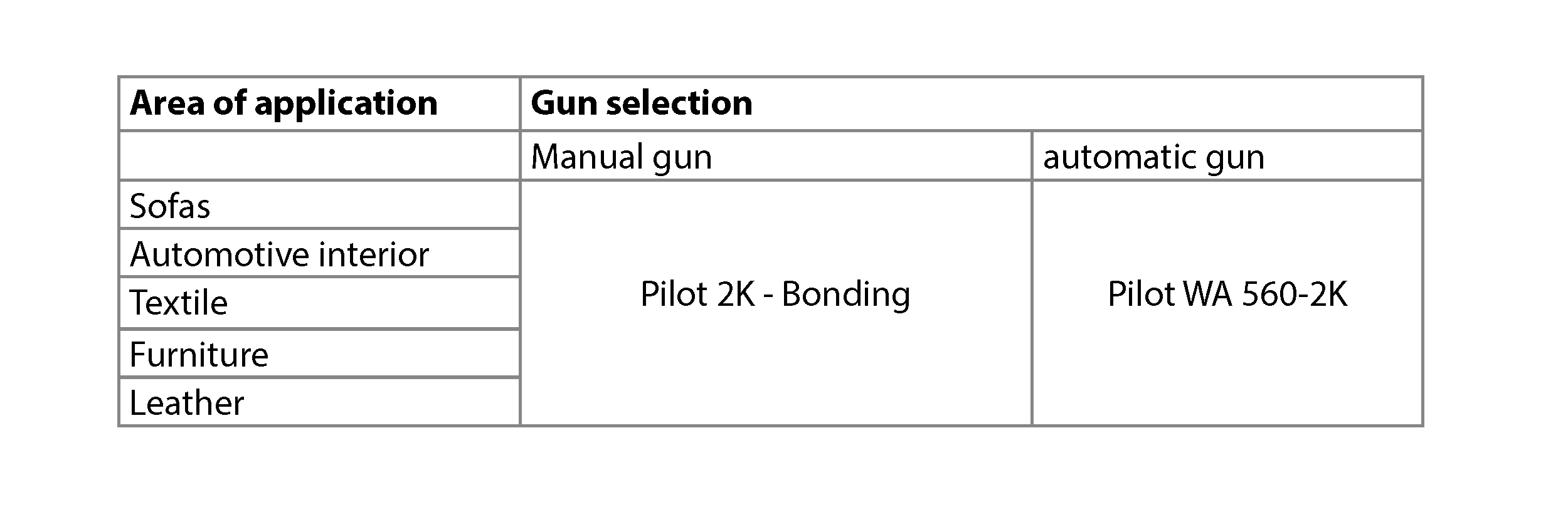

Adhesives are processed in a wide variety of industries. Whether, for example, in the upholstered furniture industry, in the leather industry or in the shoe industry. We will also find the right application system for your industry and the associated application.

Processing of adhesives

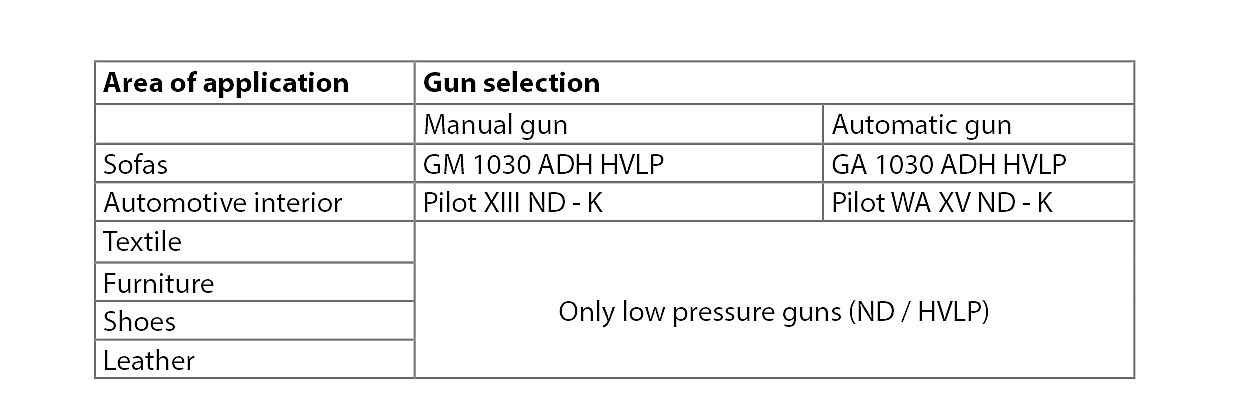

For water-based adhesives (dispersion) we recommend a low-pressure gun (HVLP), to reduce overspray and to avoid respirable droplets.

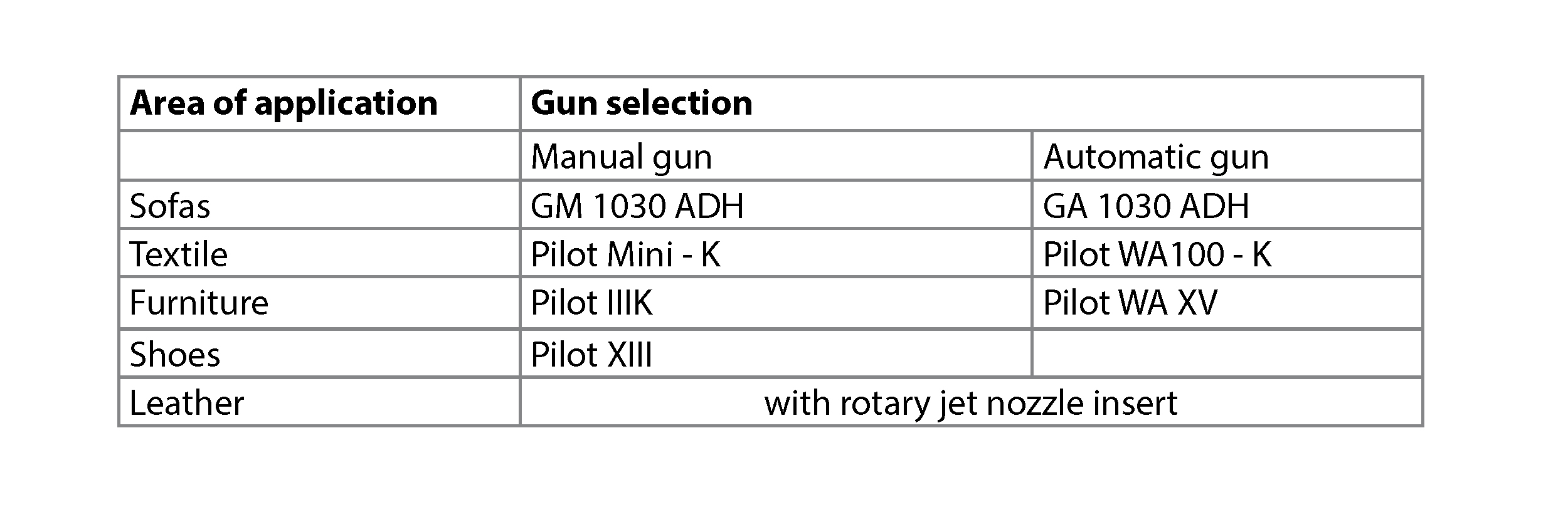

You can best process a solvent-based adhesive with a conventional atomizer and, if necessary, a rotary jet nozzle. You will need considerably more energy to achieve optimum atomization with this type of adhesive application.

Shear-sensitive media must not be exposed to high material pressure. Therefore, use a pressure tank rather than a pump to convey the material. In addition, preferably use a low-pressure gun (HVLP). When automating your adhesive application, you should resort to the variant with diaphragm needle seal.